Welcome to Foshan Pinshang Machinery Co, Ltd.

Service Hotline:

+86 13791266555

04

2024

-

09

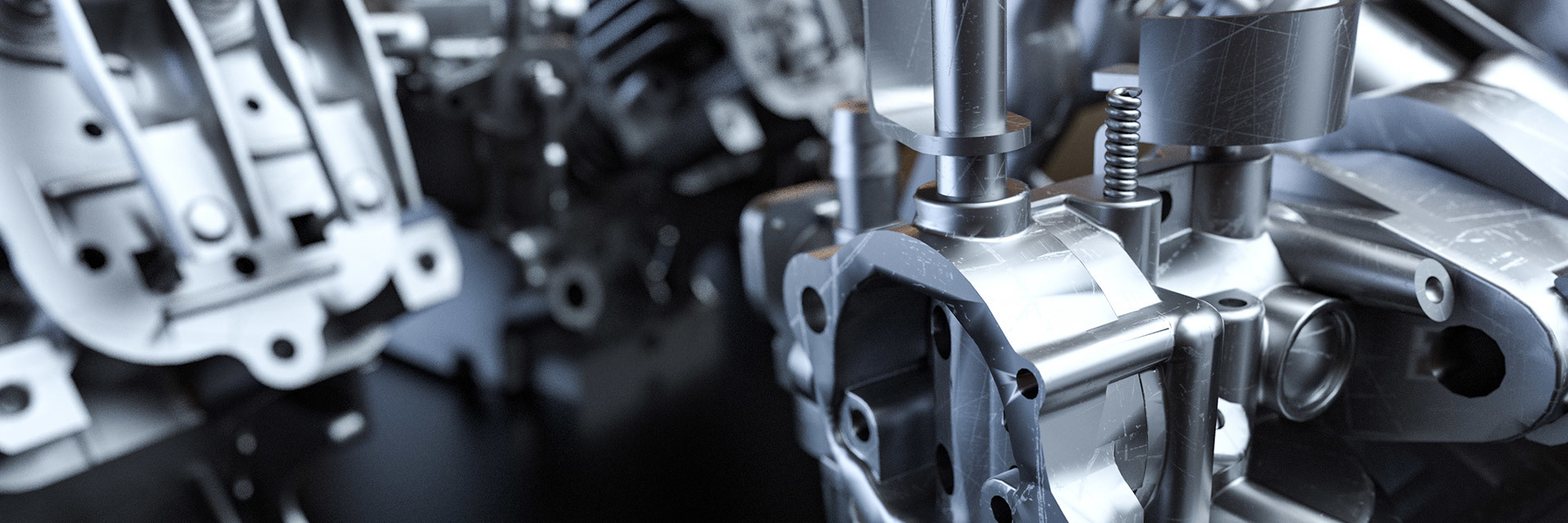

Static Maintenance of Corrugated Flexo Printer Slotter Die Cutter Machine

Category:

Static maintenance of a Corrugated Flexo Printer Slotter Die Cutter Machine is an important task to ensure that the machine stays in good condition when idle, and involves several levels of detail and consideration. The following is an in-depth discussion of static maintenance of carton presses.

1. Regulations and Standard Practices

Establishing rules and regulations for machine maintenance is a top priority. These systems should specify the machine's maintenance cycle, methods, as well as the tools and materials used.

Maintenance cycle: specify the time period of each maintenance task (such as daily, weekly, monthly, quarterly, yearly).

Operation specification: Detailed description of the maintenance steps to ensure standardized operating procedures. For example, regular oil changes, filter cleaning, checking machine accuracy, etc.

Regular oil change: Ensure that the lubrication system inside the machine works properly to reduce wear and friction.

Filter cleaning: Keeps the oil circuit clean and prevents impurities from damaging the machine.

Checking machine accuracy: to ensure the stability of printing quality.

All these maintenance activities should strictly follow the machine's manual and relevant industry standards.

2. Specialized maintenance of key components

The key components of the Corrugated Flexo Printer Slotter Die Cutter Machine, such as gears, cams, sprockets, rollers and bearings, etc., require special maintenance measures due to their high-precision characteristics. Changes in the precision of these parts will directly affect the accuracy and quality of printing.

Cleaning and lubrication: These parts are regularly cleaned and lubricated to prevent dirt and wear.

Accuracy check: Use precision measuring tools to regularly check the accuracy of these parts and adjust or replace them as necessary.

Replacement of worn parts: Replace parts that are severely worn in a timely manner to ensure the normal operation of other parts.

In addition, the spring, as a key part of the force balancing mechanism, is vital to maintain its elasticity.

Elasticity testing: Regularly check the elasticity of the spring to ensure that it can return to its original shape.

Replacement of inelastic springs: Replace springs immediately when inelastic or plastic deformation is detected.

3. Technological improvements and adaptive maintenance

With the continuous progress of technology and changes in process requirements, the Corrugated Flexo Printer Slotter Die Cutter Machine may require some technical improvements. These improvements may involve the adjustment of machine structure, upgrading of control system or the application of new materials.

Structure optimization: According to the production demand and the development of new technology, adjust the machine structure appropriately to improve efficiency and precision.

Control system upgrade: Introducing advanced control systems, such as PLC control units, to achieve more precise and stable control.

Material Replacement: Use of new wear-resistant materials can extend the service life of machine parts.

Process Improvement: According to the change of process requirements, the maintenance content will be adjusted accordingly to ensure that the machine is adapted to the new production conditions.

4. Training and education

In addition to the above specific maintenance measures, the training and education of the maintenance personnel can not be ignored. Maintenance personnel should understand the working principle of the Corrugated Flexo Printer Slotter Die Cutter Machine, structural characteristics and common faults in the treatment method.

Regular training: regular skills training for maintenance personnel, including the working principle of the machine, structural characteristics and common fault handling methods.

Technical Seminar: Organize maintenance personnel to participate in technical seminars to exchange maintenance experience and new technology applications.

Technical Documentation Study: Provide detailed technical documentation and operation manuals to help maintenance personnel gain an in-depth understanding of the functions and maintenance points of each part of the machine.

Online courses: Utilizing online education platforms to provide flexible learning opportunities, allowing maintenance personnel to improve their skills anytime, anywhere.

To summarize

The static maintenance of Corrugated Flexo Printer Slotter Die Cutter Machine is a comprehensive work, involving the establishment of rules and regulations, maintenance of key components, technical improvement and personnel training and other aspects. Through scientific and systematic maintenance measures, we can ensure that the machine in static to maintain a good state, for the subsequent printing production to provide a strong guarantee.

Related News

Service TEL:

+86 13791266555

Add:

No. 61B, Anhua Road, Fuwan Town, Hecheng Street, Gaoming District, Foshan City, Guangdong Province, China